This module is a perfect hybrid for those who own a Minitunnel and wants to perform a wood floor prefinishing with single stage coatings known also as "one-coat finishes". This category includes colored and natural oils with hard waxes as well as oils with a high solid content. The high percentage of resins and the low solvent content guarantees an excellent performance and a high saturation capacity even with a single application of between 15 and 20 gr / sqm.

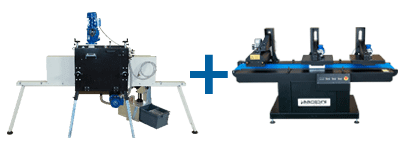

The Double Buffer Single Wiper is a machine to place after a roller coater or a Minitunnel. It polishes the oil previously applied by the vertical roller of the Minitunnel and spread by a rotating brush with tha hair in polyproyplene.

An alternative way to install this machinery and save some room is placing it “on side” of the Minitunnel. We call it “round finishing system” and it leads to some advantages:

- there is a double quality control: the final finishing is constantly checked out by two operators;

- it takes less room than a normal “in line” setup;

MACHINERY DETAILS

PAOLONI BUFING MACHINE AT WORK IN U.S.A. CUSTOMER FACTORY

WOOD FLOOR OIL FINISHING SYSTEM ON SIDE

BESPOKE TIMBER OILING FLOORING WITH PAOLONI FLOOR FINISHING MACHINES

Data Sheet

Dimensions and weight of the machine

- Length: 218 cm

- Width: 125 cm

- Height: 155 cm

- Total weight: 540 kg

Worktable size:

- Thickness min. 5 mm - max. 40 mm

- Min. Width 20 mm - max. 400 mm

- Min. Length 300 mm - max. NO LIMIT

Single-phase power supply::

- Nominal voltage: 220 V (50 Hz) (adaptable to any international standard)

- Total power 1,5 kW

Conveyor belt motor

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 1,5 kW

PAD motors with inverter

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 0,37 kW

- Adjustable speed:: min. 10 RPM - max. 150 RPM

Production speed

- Meters/minute: 1 - 19

Electric lifting of the brush with digital indicator

PAD diameter: 430 mm

Brush head inclinable +/- 35°